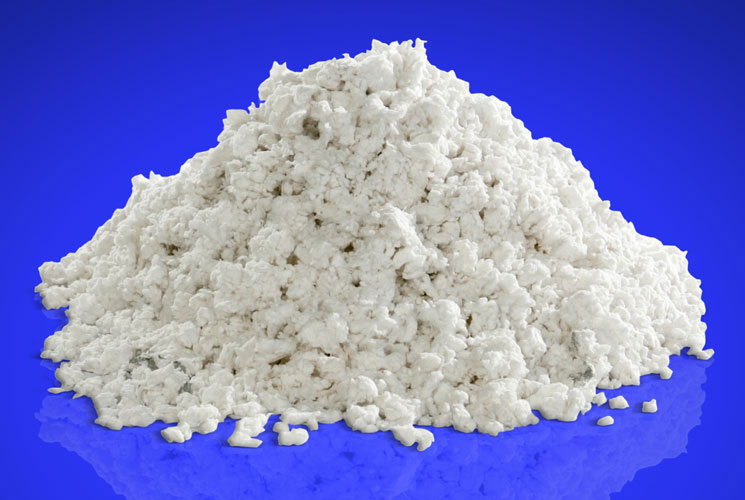

High Temperature Insulation Bulk Fibres

We offer an extensive range of high temperature insulating Bulk fibre materials for use directly as thermal insulation or for the base material in the manufacture of boards and shapes, woven into rope and cloth or blended into liquid binders for coatings and cements.

Our range comprises three fibre grades:

- Alkaline Earth Silicate Fibre (AES) bulk made from our unique low bio-persistence fibre Superwool®

- Refractory Ceramic Fibre (RCF) also known as Alumino Silicate Wool (ASW) bulk fibre made from Kaowool®, Cerafiber®, Cerachem®, Cerachrome®

- Polycrystalline (PCW) bulk fibres are manufactured by sol-gel technology using processes specifically designed to produce fibres of defined dimensions. Alphawool® bulk fibres are classified to 1600°C (2912°F).

- Engineered fibres marketed as Enfil™

AES (Superwool®)

Our Superwool® Bulk Fibres have exceptional performance-to-weight ratio, good resistance to chemical attack, high tensile strength and excellent thermal stability. For example, our Superwool® Plus™ Bulk Fibre retains its original soft fibrous structure up to its maximum continuous use temperature of 1000°C (1832°F).

Superwool® Bulk Fibres are exonerated and are not classified as carcinogenic by IARC or under any national regulations on a global basis. They have no requirements for warning labels under GHS (Globally Harmonised System for the classification and labelling of chemicals). In Europe, Superwool® fibres meet the requirements specified under NOTA Q of European Directive 67/548. All Superwool® fibre products are therefore exempt from the classification and labelling regulation in Europe.

RCF

All our RCF Bulk Fibres are resistant to chemical attack. They are lightweight, strong and feature a low heat storage capacity for effective energy savings and good thermal shock resistance for use in difficult environments. Kaowool® is classified to 1260°C (2300°F). Cerafiber® is classified to 1315°C (2400°F). Cerachem® and Cerachrome® are classified at 1426°C (2600F).

PCW

Our Alphawool® bulk fibres consists of a mass of randomly oriented, normally long, fluffy polycrystalline fibres that have an excellent thermal stability and retain their original soft fibrous structure up to maximum continuous use temperature. Alphawool bulk fibres contain no binder and do not emit fumes or smell during the first use. Bulk Fibres are a versatile feedstock for manufacturers of insulation products. We can produce them to meet specific customer specifications for composition, compressed density, fibre content, and lubricity.

Engineered fibres

Enfil™ is a family of Bulk Fibres that have been further processed to meet specific requirements for fibre index and fibre length.

They are also used directly in applications including:

- Insulation in brick wall expansion joints

- Insulating fill in chimneys and fire doors

- Kiln cars

- Cloth and textile manufacturing

- Friction modifiers in brake pads and clutch plates

- Temperature and strength modifier in paints, coatings and cements

- Base material in preforms for Metal Matrix Composites

If you would like more information on our bulk products or if you have a thermal insulation challenge for which you need assistance, and then please get in touch. We have extensive applications expertise and can work with customers to engineer optimum solutions.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Chemical Analysis, %, Weight Basis After Firing | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Availability and Packaging | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||